The global demand for botanical products has increased significantly due to rising awareness of natural remedies, herbal medicines, organic cosmetics, and plant-based wellness solutions. A well-structured botanical plant manufacturing plan is essential for entrepreneurs and businesses looking to enter or expand in this fast-growing industry. This blog explains the complete manufacturing plan, process, benefits, and key considerations for setting up a successful botanical plant manufacturing unit.

What Is Botanical Plant Manufacturing?

Botanical plant manufacturing involves the cultivation, processing, extraction, and packaging of plant-based raw materials used in pharmaceuticals, cosmetics, food supplements, ayurvedic medicines, and wellness products. These plants include herbs, medicinal plants, aromatic plants, and other natural resources with therapeutic value.

A manufacturing plan ensures consistency, quality, regulatory compliance, and scalability of botanical products.

Market Demand and Industry Growth

The botanical industry is growing rapidly due to:

- Increased preference for natural and organic products

- Rising demand for herbal medicines and supplements

- Growth in cosmetics and personal care products

- Expansion of ayurvedic and traditional medicine markets

According to industry reports, the global botanical extract market is expected to grow at a steady CAGR, making this sector highly profitable for manufacturers.

Key Components of a Botanical Plant Manufacturing Plan

A strong manufacturing plan covers infrastructure, sourcing, processing, quality control, and distribution. Below are the core components.

1. Raw Material Sourcing

High-quality raw material is the foundation of botanical manufacturing. Sources include:

- Contract farming with local farmers

- In-house cultivation of medicinal plants

- Certified organic suppliers

Proper identification, harvesting at the right maturity stage, and sustainable farming practices are critical for maintaining potency and effectiveness.

2. Manufacturing Facility Setup

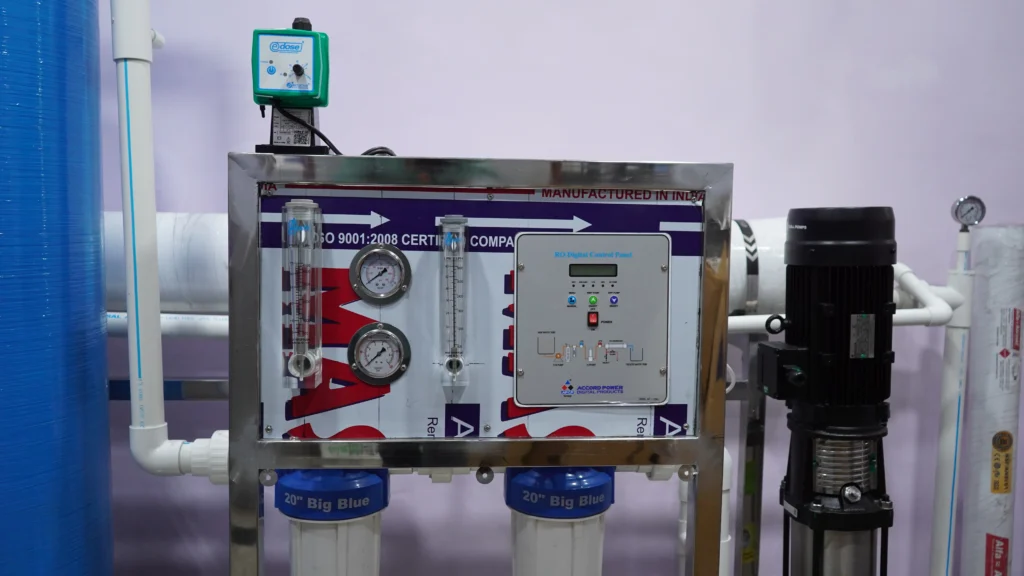

The manufacturing unit should be designed as per industry standards and regulatory guidelines. Important aspects include:

- Separate areas for cleaning, drying, grinding, extraction, and packaging

- Controlled temperature and humidity

- Hygienic storage facilities for raw and finished products

- Compliance with GMP (Good Manufacturing Practices)

Location should be easily accessible for logistics and supply chain operations.

3. Processing and Extraction Methods

Botanical plants undergo various processes depending on the final product. Common methods include:

- Drying and pulverization

- Solvent extraction

- Steam distillation

- Cold pressing

- Aqueous extraction

Choosing the right extraction technique ensures maximum yield, purity, and preservation of active compounds.

4. Quality Control and Testing

Quality assurance is a crucial part of botanical manufacturing. Testing is done at multiple stages:

- Raw material testing for purity and contamination

- In-process quality checks

- Finished product testing for potency, safety, and stability

Laboratory testing ensures compliance with pharmacopeial standards and builds trust with customers.

5. Packaging and Labeling

Proper packaging protects botanical products from moisture, light, and contamination. Packaging materials may include:

- Food-grade containers

- Glass bottles

- Aluminum pouches

- Eco-friendly packaging options

Labels must include product name, ingredients, batch number, manufacturing date, expiry date, and regulatory information.

Regulatory and Legal Compliance

Botanical plant manufacturing requires adherence to national and international regulations. Key compliances include:

- GMP certification

- Ayush license (for herbal and ayurvedic products)

- FSSAI approval (for food supplements)

- Environmental clearance

- Export certifications if targeting global markets

Compliance ensures smooth operations and long-term business sustainability.

Sustainability and Environmental Responsibility

Modern manufacturing plans focus heavily on sustainability. Best practices include:

- Ethical sourcing of plants

- Water and energy conservation

- Waste management and recycling

- Use of renewable energy

- Avoiding overharvesting of medicinal plants

Sustainable practices enhance brand reputation and meet global environmental standards.

Workforce and Skill Requirements

A trained workforce is essential for efficient manufacturing. Key roles include:

- Botanists and agronomists

- Quality control analysts

- Production supervisors

- Skilled machine operators

- Regulatory and compliance officers

Continuous training ensures adherence to quality and safety standards.

Cost Structure and Investment Planning

The cost of setting up a botanical manufacturing unit depends on:

- Land and building

- Machinery and equipment

- Raw material procurement

- Licensing and certifications

- Labor and utilities

A detailed financial plan helps estimate ROI and profitability while minimizing operational risks.

Distribution and Marketing Strategy

A successful manufacturing plan also includes a clear go-to-market strategy:

- Supplying to pharmaceutical and cosmetic companies

- Private labeling for brands

- Online and offline distribution channels

- Export opportunities

Strong branding, certifications, and quality consistency play a key role in market penetration.

Benefits of a Well-Defined Manufacturing Plan

- Consistent product quality

- Regulatory compliance

- Cost optimization

- Scalable operations

- Long-term business growth

Conclusion

A well-designed botanical plant manufacturing plan is the backbone of a successful herbal and botanical business. From raw material sourcing to processing, quality control, sustainability, and marketing, every step must be carefully planned and executed. With increasing global demand for natural products, investing in botanical manufacturing offers strong growth potential and long-term profitability.

By following best practices and maintaining high-quality standards, businesses can build a trusted brand in the competitive botanical industry.