Water quality plays a critical role in industrial operations across manufacturing, pharmaceuticals, food processing, hospitality, and commercial facilities. Choosing the best industrial RO plants for businesses ensures consistent water purity, operational efficiency, and long-term cost savings. This blog provides a complete SEO-optimized guide to help businesses select the right industrial reverse osmosis (RO) system based on capacity, application, and performance.

What Is an Industrial RO Plant?

An industrial RO plant is a high-capacity water purification system that uses reverse osmosis technology to remove dissolved salts, chemicals, heavy metals, bacteria, and other contaminants from raw water. Unlike domestic RO systems, industrial RO plants are designed for continuous operation, high flow rates, and demanding industrial environments.

Industries rely on RO-treated water for production processes, boiler feed, cooling systems, and product quality assurance.

Why Businesses Need Industrial RO Plants

Investing in a high-quality industrial RO plant offers multiple benefits:

- Consistent supply of purified water

- Improved product quality and safety

- Reduced equipment scaling and corrosion

- Compliance with industrial water standards

- Lower maintenance and operational costs

For businesses aiming at sustainability and efficiency, RO plants are no longer optional—they are essential.

Types of Industrial RO Plants

1. Brackish Water RO Plants

These systems are ideal for treating groundwater and borewell water with moderate TDS levels. They are commonly used in:

- Manufacturing units

- Hotels and hospitals

- Educational institutions

Brackish water RO plants offer high recovery rates and energy-efficient performance.

2. Sea Water RO Plants

Designed for very high TDS water, sea water RO plants are suitable for coastal industries, ports, and offshore facilities. They feature:

- High-pressure pumps

- Specialized membranes

- Corrosion-resistant materials

3. Containerized RO Plants

Containerized industrial RO plants are pre-assembled systems installed inside shipping containers. They are ideal for:

- Remote locations

- Temporary industrial setups

- Quick deployment projects

These plants offer flexibility and reduced installation time.

Key Factors to Choose the Best Industrial RO Plant

1. Water Quality and TDS Level

Understanding raw water parameters such as TDS, hardness, iron content, and microbial load is crucial. A proper water analysis helps determine:

- Membrane type

- Pre-treatment requirements

- System design

2. Capacity Requirement

Industrial RO plants are available in various capacities, ranging from 500 LPH to 1,00,000 LPH and above. Businesses must calculate daily water consumption to avoid under-sizing or over-sizing the system.

3. Pre-Treatment System

Pre-treatment improves RO membrane life and system efficiency. It may include:

- Pressure sand filters

- Activated carbon filters

- Softener or dosing systems

A strong pre-treatment setup is essential for long-term performance.

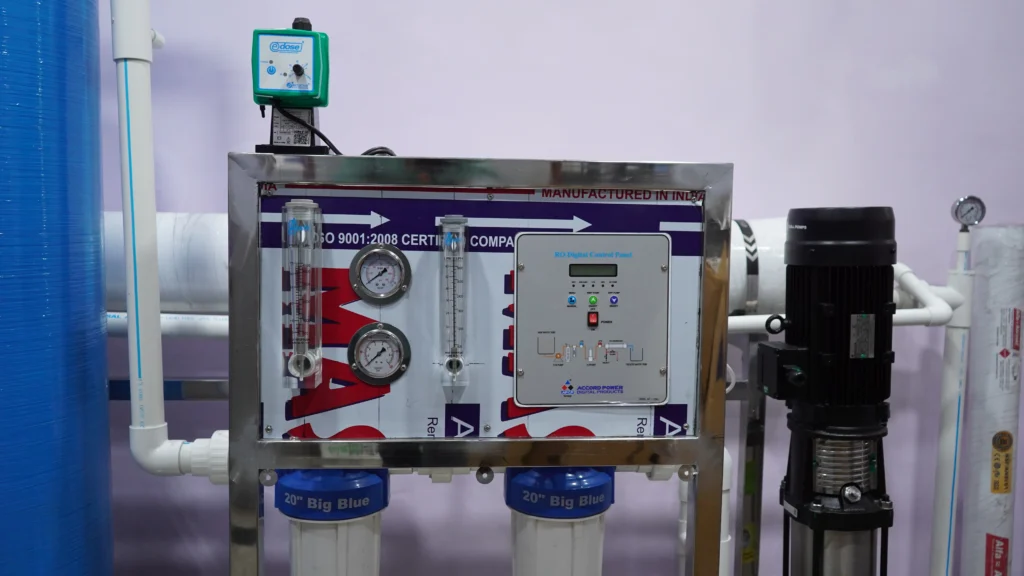

4. Quality of Components

The best industrial RO plants use high-quality components such as:

- International-standard RO membranes

- Stainless steel or FRP pressure vessels

- Energy-efficient high-pressure pumps

- Reliable control panels

Premium components reduce downtime and maintenance costs.

5. Automation and Control

Modern RO plants come with automated features like:

- PLC or microprocessor-based control panels

- Auto-flush systems

- Low-pressure and high-pressure safety switches

Automation improves operational reliability and reduces manpower dependency.

Best Industrial RO Plants for Different Business Sectors

Manufacturing Industries

Manufacturing units require RO plants for process water, cooling systems, and boiler feed. High-capacity and continuous-duty RO plants are ideal for this sector.

Food and Beverage Industry

RO plants used in food processing must meet hygiene and safety standards. Systems with food-grade components and precise TDS control are preferred.

Pharmaceuticals and Healthcare

Pharmaceutical companies require ultra-pure water for formulations and cleaning. Multi-pass RO systems with advanced filtration are commonly used.

Hotels, Malls, and Commercial Buildings

Commercial establishments use RO plants for drinking water, kitchens, laundry, and HVAC systems. Compact and energy-efficient RO plants work best.

Maintenance and Operating Cost Considerations

To ensure long-term performance, businesses must consider:

- Regular membrane cleaning and replacement

- Filter media replacement

- Power consumption

- Service and spare part availability

Choosing a trusted RO plant manufacturer with after-sales support significantly reduces lifecycle costs.

Energy Efficiency and Sustainability

Modern industrial RO plants are designed with sustainability in mind. Features such as:

- Energy recovery devices

- High-rejection membranes

- Optimized recovery rates

help reduce water wastage and electricity consumption, supporting eco-friendly business operations.

How to Select the Right RO Plant Manufacturer

Selecting the right supplier is as important as choosing the system itself. Look for manufacturers who offer:

- Customized RO plant solutions

- Site inspection and water testing

- Installation and commissioning support

- AMC and technical service

A reliable manufacturer ensures system longevity and consistent water quality.

Conclusion

Choosing the best industrial RO plants for businesses requires careful evaluation of water quality, capacity needs, system design, and manufacturer expertise. A well-designed industrial RO plant not only improves water quality but also enhances operational efficiency, reduces costs, and supports sustainable business growth.